MSI is working on an artificial intelligence model-oriented ecosystem in the CAPRI Steel use case

Within an artificial intelligence model-oriented ecosystem such as the CAP of the CAPRI project, one of the most important elements are data acquisition and data integrity. Through the gathering of large sets of historical process data, CAPRI partners will be able to train complex algorithmic models that later in production can be used to, this time using real-time data, predict unwanted dynamics in the production environment.

With this premise, data acquisition and validation become tremendously important to avoid introducing biases to the algorithmic model that result in an unreliable prediction.

Industrial environments are diverse and complex, and this means that data acquisition must be very flexible and at the same time very robust from a connectivity point of view. For this purpose, the use of IIoT devices and opensource software such as Node-Red are gradually becoming industrial standards because of their usability and robustness in operations.

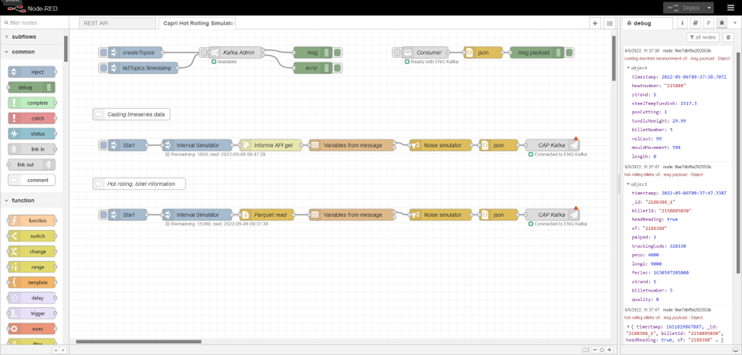

In the CAPRI steel use case, MSI has implemented Node-Red as a cohesive element of the data in the use cases, since it allows to replicate the existing data ecosystem in the plant.

Having a diversity of data sources such as Informix databases, Parquet files from IBA, Scadas, OPC-UA type services, etc., a replica of this architecture has been created in the laboratory of MSI “populated” with historical data in order to allow other partners to train the algorithmic models by accessing all these data easily through a REST API.

In addition, given the slow nature of steel manufacturing processes, this historical data will be used as the basis for accelerated simulations of the process with the addition of noise, disturbances, and new events so that predictive algorithms can be validated in scenarios never seen before by these models. In this task the live data will be accessible through the REST API mentioned above and will also be published to an Apache Kafka broker for real-time processing.

Once the training and validation processes are completed, the same IIoT elements used in the laboratory can be installed in the use case facilities, so they can be connected to the real data instead of simulated data to feed these algorithmic models in the same facilities, all deployed in EDGE technology to have real time and low latency predictions.