Ensuring flexibility and scalability in Digital Transformation for Process Industry: the Cognitive Automation Platform experience

The Energy-Intensive Industries ecosystem employs 7.8 million people in Europe and provides an added value of EUR 549bn (4.55% of the EU total). In 2019, they were responsible for 22% of total EU greenhouse gas emissions[1]. According to the European Green Deal[2], digital transformation represents a key enabler for attainaing the European sustainability goals in many different sectors, represented in this ecosystem by chemicals, steel, non-ferrous, metals, refineries, mining, extraction and quarrying, glass, ceramics, paper, and more others.

According to the European co-programmed Partnership dedicated to the Process Industries - Process4Planet, digitalisation will happen horizontally and cover the entire life cycle, including R&D, plant operations, supply chain management, customer relations and integrating material flows in a circular economy and across industry sectors[3].

The CAPRI project concept is based on the above mentioned assumptions and strongly believes that edge computing technologies – working cohesively with diverse heterogeneous technologies, such as algorithms, sensors, data, artificial intelligence, machine learning and energy storage – have the potential to develop significant business benefits and fundamental changes in the way we live and work[4].

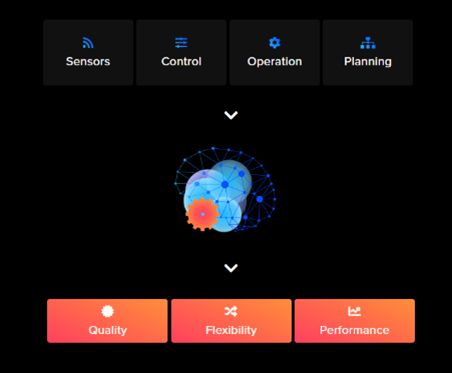

Thus, Artificial Intelligence, Machine Learning and Edge Computing are the main technologies at the basis of the developed Cognitive Solutions, representing a breakthrough innovation for Plant Operations and Supply Chain management.

In our previous article “Industry 4.0 revolution and the smart factory in process industry”, it has been described the Cognitive Automation Platform (CAP)[5] and its reference implementation, based on major Open Source frameworks (i.e. FIWARE, APACHE, etc.). We highlighted the main elements which enables Industry 4.0 revolution and the application of Zero-Defect Manufacturing principles and Predictive Maintainance purposes to the project objectives.

Nevertheless, ambitious objectives include relevant challenges!

We asked our ENGINEERING’s Researchers, Gabriele De Luca and Mattia Marzano, the main barriers they met to integrate the developed Cognitive Solutions in the Cognitive Automation Platform and what they have done to define appropriate and tailored solutions to overcome the incurred issues.

Mattia, can you please describe briefly the objective of the Cognitive Automation Platform?

The Cognitive Automation Platform aims to cover the entire data flow, starting from the data collection from heterogeneous sources until the data consumption. It allows to persist incoming data from the smart field, such as the data outcomes, by the integrated Cognitive Solutions, providing at the same time a business analytics suite based on machine learning and cognitive algorithms. Security modules for the user management and the support for the Data Sovereignty principles are also integrated. The CAP Platform uses a lego approach for its implementation, it means that who wants to adopt the platform can select the components needed based on open-source technologies. The Platform has been designed in order to be flexible, also in the case of integration with proprietary components, ensuring its extensibility and scalability. The result is a customizable and integrable Platform, with many existing solutions boosting the functionalities and features on a tailored approach.

Gabriele, can you please tell us which barriers ENGINEERING encountered to integrate the Cognitive Solutions into the Cognitive Automation Platform?

The main barriers we encountered are mainly related to data availability. In the process industry, machines cannot be stopped at any time. Furthermore, the available (and shareable) data are not always useful in terms of quality and quantity. In order to overcome these barriers, we included the simulation (and emulation in the steel domain), iteratively improving and refining the platform elements once new datasets have been made available. The approach followed supports the Agile Manifesto principles, making the integrated Cognitive Solutions ready for deployment at company premises, and allowing the plug-and-play of real machines and devices already tested in a simulated environment.

Mattia, what has been done to ensure the scalability of the Cognitive Solutions and of the Cognitive Automation Platform?

The process started from the design of the Reference Architecture, where the aim was to reach a level of performance, scalability, and reliability better than the solution previously used. The Reference Architecture allows the scalability of the platform itself, integrating the Cognitive Solutions designed and developed by the project partners. This has been ensured using Apache Spark, identified as the most used tool in the different application domains. In the same way, the usage of Docker for the components selected for the deployment ensures the scalability not only of the platform, but also in terms of the single developed technology.

Gabriele, what are the future purposes of the project and what is going to be the ENGINEERING’s role?

These days we are accomplishing the integration of Cognitive Solutions, and, at the same time, we are bringing the already integrated solutions to the company premises, ready to be used and exploited. Engineering is also working on the release of the CAPRI Blueprints, aiming to share and push the adoption of the Cognitive Automation Platform in the Process Industry contexts.

As described by ENGINEERING’s colleagues, the major gaps were represented by the complexity of data, insufficient data quality as well as the lack of IT Infrastructure readiness, similarly to the results presented by the AI CUBE project during the last PI HUB Annual Meeting organised by the CAPRI project.

With 2022 drawing to an end, the CSs’ integration in the Cognitive Automation Platform begins to produce value for CAPRI pilots. Going forward, all project partners will keep refining and tuning each of their deployments with ENGINEERING’s colleagues supporting in the process.

[1] European Commission e “Investment Support for Energy Intensive Industries”, 2022

[2] COM (2019) 640 – Commission “The European Green Deal”

[3] Process4Planet European Co-programmed Partnership, 2021, Strategic Research and Innovation Agenda 2050

[4] SWD (2022) 41 - Commission Staff Working Document “EU strategic dependencies and capacities: second stage of in-depth reviews”

[5] Antonio Salis A., Marguglio A., De Luca G., Razzetti S., Quadrini W., Gusmeroli G., 2022, "An Edge-Cloud based Reference Architecture to support cognitive solutions in the Process Industry". https://arxiv.org/abs/2202.06622